Even once part design and mold design are fixed, there are still options to improve weldlines. Have a look below for inspiration on troubleshooting or contact one of our experts!

Pressure control

- Optimize the switch-over point to the holding pressure: shortly before the volumetric filling has been reached (approximately 98 % of the filling level ), change over to holding pressure.

- Higher holding pressure (better compensation shrinkage at weldline)

Venting is essential for injection molded parts, and in particular for the quality of weldlines. If number of vents, their locations and dimensions cannot be changed, it's still important to check if all vents are clean and function as intended.

Filling speed

The filling speed is an important parameter for injection molding and is closely correlated to the filling pressure (see graphs on the right).

Improvements with respect to weldlines can often be achieved by increasing the injection speed to avoid early cooling. However, if venting problems are encountered in the area of the weldline, the injection speed should be reduced.

Flow pattern

- Altering the flow pattern can adjust the weldline location to a less critical spot of the part.

- Cascade injection: Using cascade injection (for multipe gates) it's possible to increase the surface area at the weldline location, thus creating a stronger connection between the two melt fronts.

The image on the left shows an example using meltfronts of the same material with and without colorant.

Temperature control

- Increase meld/mold temperature to achieve improved healing.

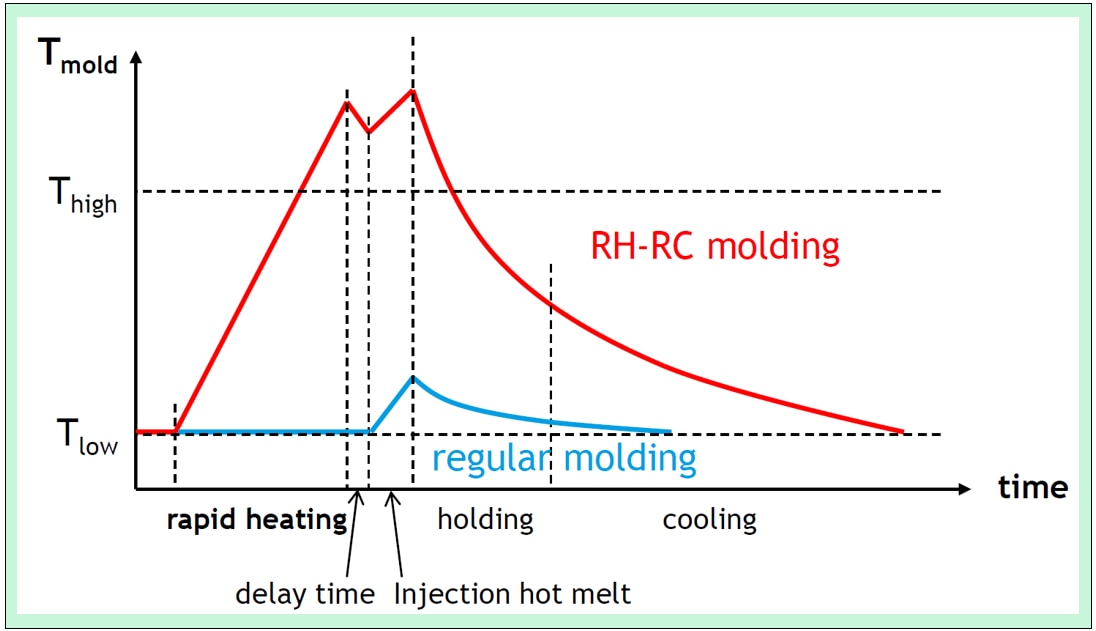

- Rapid-heat rapid-cool molding: In contrast to regular molding, in RH-RC molding the mold is heated to a higher temperature, which improves the melt flow. After injection, a longer period of cooling is required. This method can improve weldline quality, but takes somewhat longer in processing.